What is a Kettle Type Reboiler Distillation column?

Distillation columns will use various heat transfer equipment for the liquid-vapor separation to occur. One of the many auxiliaries is the reboiler, located at the bottom of the distillation column setup. They reheat and recycle the bottoms product so its vapors return to the column, improving the separation efficiency of the process.

There are many types of reboilers, but in this section, we will discuss the simplest kind of reboiler — the kettle type reboiler

A kettle type reboiler is a total reboiler — meaning it completely transforms liquid into vapor under equilibrium conditions.

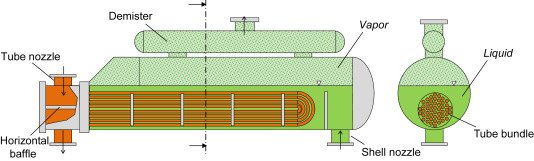

Kettle type reboilers are characterized by their horizontal length and liquid storage. This type of reboiler holds the bottoms liquid in its shell where the liquid comes into contact with a tube bundle containing the heating medium. Kettle type reboilers are a type of shell-and-tube heat exchangers.

A tube bundle is a number of pipes containing a heating medium, commonly saturated steam, that provides heat to the fluid. Baffles are located along the length of the reboiler to help facilitate movement and heat transfer in the reboiler. Eventually, the fluid undergoes a phase change from liquid to vapor. Along the length of the reboiler are also nozzles for the feed and vapor streams.

On top of the reboiler is a demister. The demister removes condensation carried by the vapor flow, which can be a safety hazard if it comes in contact with the turbine.

In a kettle reboiler, the vapor and liquid phases are in equilibrium, thus making it an ideal stage.

Kettle reboilers have many benefits. First, they are insensitive to system hydraulics which makes them reliable at extreme pressure changes (vacuum or near-critical pressures), and they work despite having low temperature changes as driving forces.

Because kettle reboilers are designed for low circulation, they tend to have high fouling rates. In addition, kettle reboilers are also designed with thicker shells and contain more liquid, which makes them more expensive to construct.

Kettle-type reboilers are placed beside the bottom of a distillation column since it receives any bottom liquids coming from the distillation column.

Gravity moves a portion of the feed into the reboiler, where the fluid comes into contact with the tubes containing the heating liquid. The fluid must constantly submerge the bundle tubes to avoid overheating, energy waste, and excess fouling in the reboiler. Once the fluid boils on the surface of the tubes, the vapor then rises from the reboiler and returns to the distillation column to undergo the vapor-liquid separation process over again.

Any unvaporized material left in the reboiler goes over the weir, staying there until it reaches a specified level. Once that level is reached, the weir drains, and that unvaporized material exits the reboiler as the bottoms stream.

1. What is the difference between boiler and reboiler?

A reboiler is a heat exchanger situated at the bottom of distillation columns. It reheats and recycles fluid to produce vapors under equilibrium conditions. It is considered one theoretical stage in the distillation process.

A boiler produces water vapor (such as steam) under specific conditions by burning a fuel source. The water vapor produced by the boilers is then used to drive turbines, engines, and the like.

2. What is the difference between a reboiler and an evaporator?

An evaporator’s main purpose is to concentrate a solute in a solution by evaporating the solvent at the right temperature and pressure conditions.

On the other hand, the reboiler’s main purpose is to reheat fluids so that their vapors may undergo heat and mass transfer in the distillation column.

3. Is a kettle reboiler a partial reboiler?

No. Kettle reboilers totally convert a liquid into a vapor, which makes them total reboilers.

4. Is a kettle reboiler a heat exchanger?

Yes, kettle reboilers can be considered heat exchangers in the broadest sense since there is heat transfer between the bottoms fluid in the reboiler and the heating fluid.

5. How many types of reboilers are there?

There are four major types of reboilers, with each reboiler having variations depending on its use and design. They are mainly kettle reboilers, thermosyphon reboilers (vertical, horizontal), forced flow reboilers, and internal reboilers.

Astolfi, M. Technical Options for Organic Rankine Cycle Systems. Elsevier Ltd., 2017. Elsevier.

Accessed 3 June 2022.