Reboilers are heat exchangers that generate vapor in a distillation column. The liquid collected at the bottom of the distillation column vaporizes multiple times (thus the term “reboiler”) by means of a service stream (steam, oil, etc.).

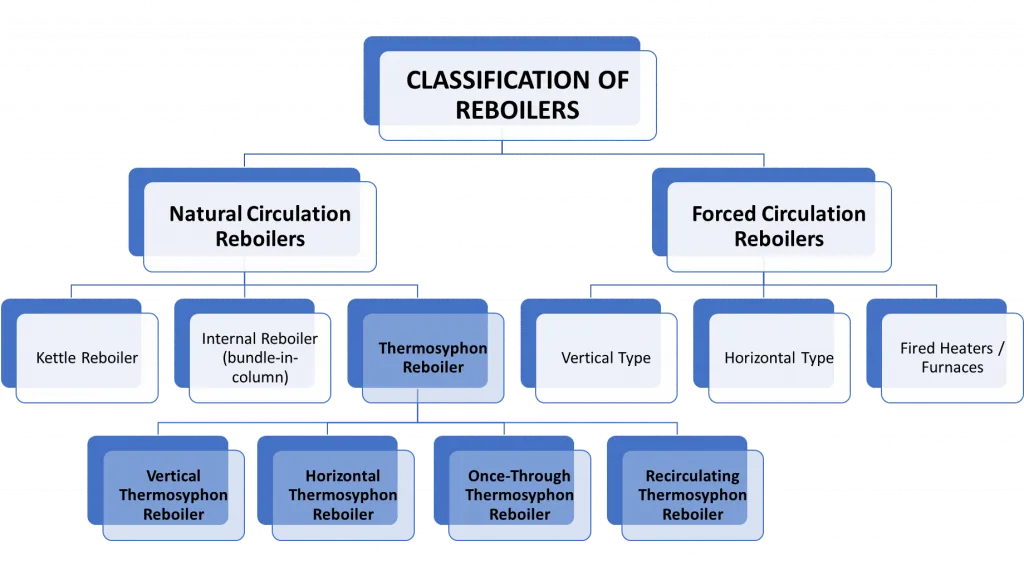

There are 2 main classifications of reboilers — Natural Circulation Reboilers and Forced Circulation Reboilers.

Natural circulation reboilers use a gradient (pressure, density, or temperature) between reboiler inlet column bottoms liquid and reboiler outlet liquid-vapor mixture to circulate the vapor in the distillation column.

Meanwhile, forced circulation reboilers use a pump to provide the needed head to deliver the tower bottoms into the reboilers.

A thermosyphon reboiler is a type of natural circulation reboiler that utilizes the difference in density between the inlet liquid and outlet vapor-liquid mixture to provide the needed head to circulate the column bottoms into the reboiler.

They are used commonly in distillation, stripping, and absorption towers in chemical, petrochemical, and refining industries. About 70% of vertical reboilers used in petrochemical industries are thermosyphons.

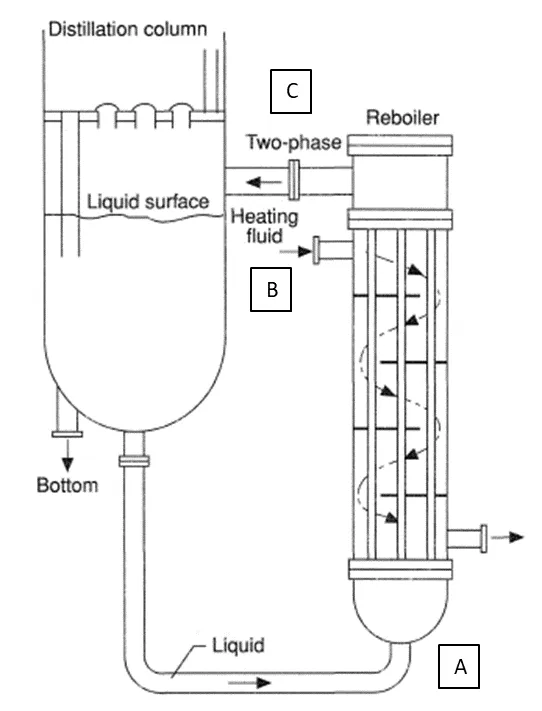

Here’s a sample process flow diagram of a vertical thermosyphon reboiler:

The video below will give you a better understanding on what happens inside a thermosyphon reboiler. This example uses amine as the process fluid, and low pressure steam as the heating fluid.

Thermosyphon is a flow driven by density gradient caused by natural or passive convection. Here’s how the principle works:

This thermal expansion causes a gradient between the densities of the process fluid at the inlet and at the outlet of the reboiler. In thermosyphon reboilers, the vapor generated has higher convective pressure than the bottoms liquid, thus generating enough pressure and velocity to circulate the vapor-liquid mixture in the reboiler and back to the column.

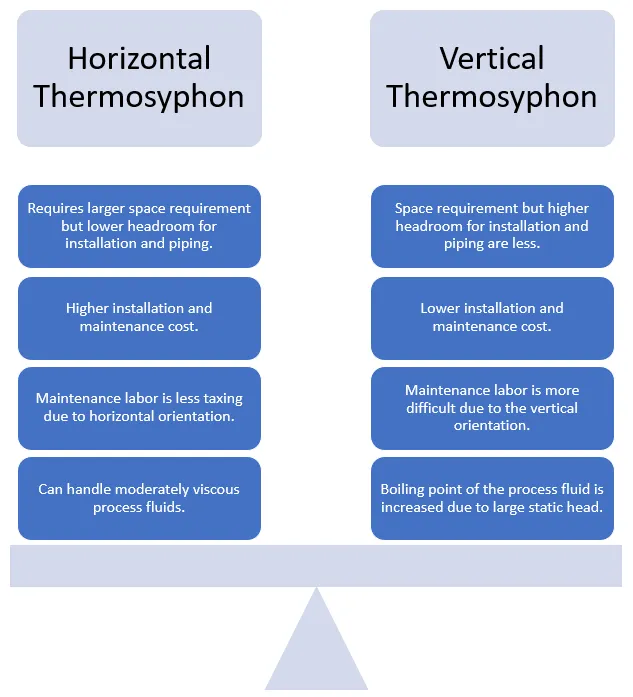

The key differences between vertical and horizontal thermosyphon reboilers are the following:

Criteria | Horizontal Thermosyphon | Vertical Thermosyphon |

Process Diagram (Source: Thermopedia.com) | ||

Reboiler Orientation | Tubes are parallel with the ground | Tubes are perpendicular to the ground. |

Fluid Flow | Process fluid passes through the shell side while heating fluid passes inside the tubes. | Process fluid passes through the tube while heating fluid passes through the shell side. |

Reboiler Construction | Can be multiple pass tubes covered by TEMA G, TEMA H, or TEMA X shell. | Usually single tube covered by TEMA E shell |

Thermosyphon reboilers can also be classified based on the manner in which the liquid in the vapor-liquid mixture is utilized. In once-through thermosyphon reboilers, the liquid part flows over the weir, is not recycled as reboiler feed, and exits the process in the bottoms. Recirculating thermosyphon reboilers recycle the liquid phase and recirculate it to the reboiler multiple times as process fluid.

Nearly 100% of thermosyphon reboilers used in chemical refining industries are vertically oriented. In comparison, 95% of horizontal reboilers in the petroleum industry are thermosyphons. You might ask — how do you choose which type of thermosyphon to use?

Selection criteria include the following:

Criteria | Horizontal Thermosyphon | Vertical Thermosyphon |

Area Allocation | If lower headroom but a larger area is available | Suitable for installation with limited area, but higher headroom |

Process Fluid Viscosity | Preferred when process fluid viscosity is > 0.5 cp | More suitable for less viscous and more volatile process fluids. |

Heat Transfer Area | Preferred when heat transfer area requirement is large | Higher heat transfer rates |

Circulation Rate | Preferred when low static head and high circulation rate is required. | Used for high circulation rate, considerable difference in static head, |

In addition, the advantages and disadvantages below for each type will help you maximize efficiency and reduce operational and maintenance costs.

In a kettle type reboiler, the process liquid flowing in the shell side must completely submerge the tube containing the heating fluid at all times to allow for a highly effective heat transfer for a single pass. The TEAM K shell specifically used in kettle type reboilers allows the separation of liquid and vapor inside the shell, allowing only vapor to be directed back to the column.

In a thermosiphon reboiler, passive convection triggers boiling and a two-phase (vapor-liquid) mixture is circulated back to the column.

Fouling is common especially when process fluid contains suspended particles that can deposit scales on the tubes and shell. Also, in critical conditions when the vapor and the liquid have almost the same densities, the generated head is too small to provide circulation.

One Response

Thanks for sharing the information regarding the Thermosyphon Reboiler. In this blog, you describe the Working Principles of thermosyphon. it is helpful for us. Keep sharing more details.