Distillation is the process of separating the components of liquid-liquid and vapor-liquid mixtures by selective evaporation and condensation. Either a batch or continuous approach may result in complete separation of nearly pure substances or partial separation, in which a higher concentration of specific substances is achieved.

Though knowledge of the liquid mixture component’s volatility is key to the efficiency of the separation process, the distillation equipment in which the separation process is performed (called a distillation column) plays a major role.

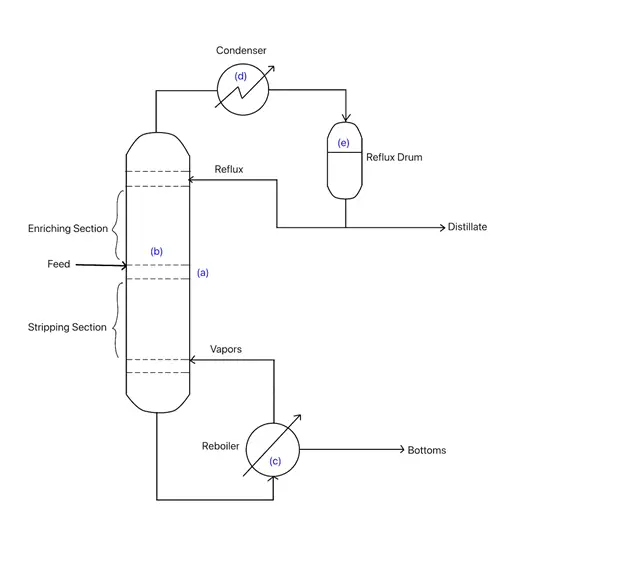

There are various components in a Tray distillation column:

(a) A vertical shell in which the separation process is performed;

(b) Distillation column internals that enhance the separation process of each component (these could be in the form of trays, plates, or packings);

(c) A reboiler which provides the necessary vaporization for the distillation process;

(d) A condenser to cool down the vapors leaving the top of the column, converting them back into liquid form (called condensate);

(e) A reflux drum to hold the condensed vapor from the top of the column so that liquid (reflux) can be recycled back to the column.

Tray Distillation column internals promote vapor-liquid contact so that every theoretical stage achieves equilibrium efficiently — enhancing the separation process of each component of the liquid mixture. Factors such as the geometry of distillation column internals affect the extent and type of contact between the vapor and liquid streams.

There are 2 general types of distillation column internals:

In general, distillation trays are used for applications with liquid rates of 30 m3/m2-h and above, and/or those where solids are present or fouling is a concern. Trays are designed to provide liquid holdup (stepwise contact) to achieve the proper vapor-liquid mass transfer that the distillation process requires for separation.

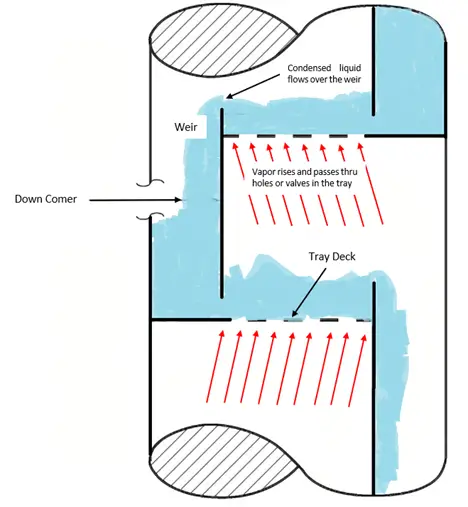

The holdup is achieved by a weir on each tray and stacks of horizontal trays that allow liquid to run across a tray before flowing over a downcomer and moving to the next stage of the distillation process. Flow across the trays allows upward-moving vapors and downward-moving liquids to have intimate contact in strategically placed passages in the tray (e.g., valve trays, bubble cap trays, sieve trays).

On the other hand, packings are used in lower liquid rate applications (less than 50 m3/m2-h), especially when minimizing pressure drop within the column is desired. They provide a large amount of surface area per unit volume to facilitate the vapor-liquid mass transfer. Unlike the stepwise contact in distillation trays, a packed bed allows for continuous contact between the vapor and the liquid on the surfaces of the packing.

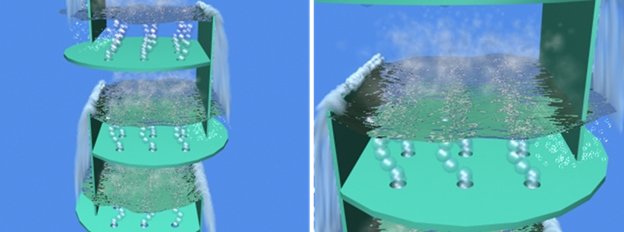

The sieve tray is the simplest type of cross-flow plate. The tray contains small round holes, perforations ranging from 1/8 to 1 inch which are punched through the tray deck. Vapor rises through the perforations on the tray floor and bubbles through the liquid in a fairly uniform manner. The liquid then flows across the tray floor over the weir, through the downcomer to the tray below.

The holes on the tray give a multi-orifice effect. The vapor velocity keeps the liquid from flowing down through the holes. Liquid flow is transported down the tower by downcomers, and weir to overflow device to the side of the tray. In sieve plates, the liquid is prevented from flowing through the sieve tray perforations by the upward flowing action of the gas. Thus, when the gas flow is low, it is possible for some or all of the liquid to drain through the perforations, and in effect, bypass portions of the contacting zone. This phenomenon is called weeping.

The function of a tray is to mix the vapor and liquid together to form a foam. Vapors bubble up through the tray sieve holes, where the vapor comes into intimate contact with the liquid. The fluid on the tray is a mixture of vapor and liquid in the form of froth or foam. This foam should separate back into a vapor and a liquid on the tray and in the downcomer. If the foam cannot drain quickly from a downcomer onto the tray below, then the foamy liquid will back up onto the tray above. This is called flooding.

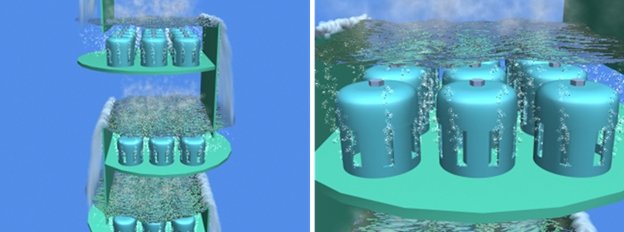

In bubble cap trays, vapors rise up through risers or chimneys into a cap, then come out from slots or holes in a cap and bubble through the surrounding liquid on the tray. Vapors and liquid are in total contact for their mixing and mass transfer. Liquid flows over the caps on the tray from the upper downcomer to the outlet weir and downcomer to the tray below. A liquid head is maintained on the tray by an outlet weir near the downcomer.

The openings in valve trays are covered with liftable caps that adjust themselves according to the vapor flow. Tray valves or caps close off at a low vapor rate, stopping the liquid from moving down from the tray. As the vapor rate increases, the valve lifts, and the open area for vapor flow also increases.

The valves on the trays can be fixed or moving. The fixed valves are permanently open while the moving valves adjust themselves according to the vapors flowing up through the tray. Hence, valve trays can operate over a wide range of flow rates with high separation efficiency and large flexibility.

The valve plate is designed to minimize “weeping”. Since the valve tends to close as the gas flow becomes lower, the total orifice area varies to maintain a dynamic-pressure balance across the plate. Because of their flexibility and reasonable price, valve trays tend to replace the bubble-cap trays.

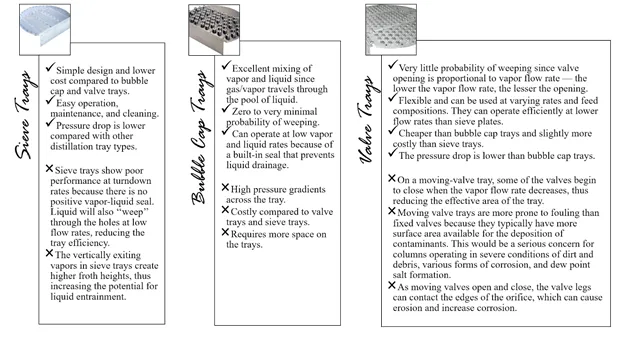

In summary of the comparison among the distillation trays, here are their advantages and disadvantages:

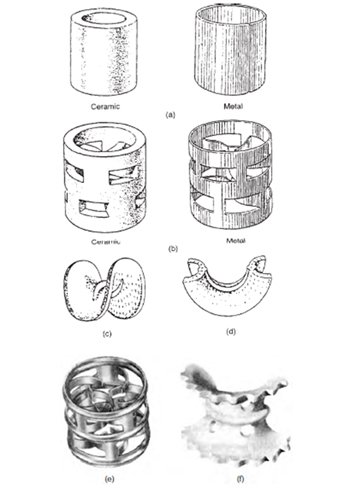

Random packed towers are constructed using a variety of metal or nonmetal materials, such as plastics and ceramics. These materials provide the surface area needed for the distillation process. When it comes to packings, a good wettability is desired since a higher wetted area increases the interfacial area where vapor and liquid come in contact for mass and heat transfer.

The packing materials can be made from metal, plastic, or ceramic.

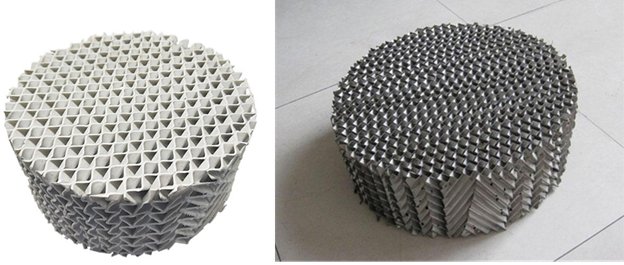

Compared to random packings, structured packed towers offer more surface area and have a lower pressure drop. Structured packing can be manufactured from corrugated sheets of perforated embossed metal, plastic (including PTFE), or wire gauze. The result is a very open honeycomb structure with vertical flow channels giving a relatively high surface area to volume but with a very low resistance to flow. The surfaces have been chosen to maximize liquid spreading. These characteristics tend to show significant performance benefits in low pressure and low flow rates per cross-sectional area of the column.

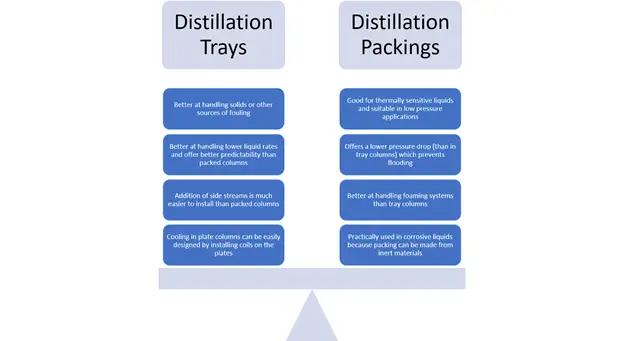

Understanding the pros and cons of different column internal options types is key to efficient design practice. In general, the application suitability depends on the nature of feed and flow rates.

Trays are used in applications with liquid rates of 30 m3/m2-h and above, and/or those mixtures where fouling is a concern whilst packings are used in lower liquid rates (less than 50 m3/m2-h) and minimizing pressure drop within the distillation column is desired.

However, these liquid rate guidelines are not absolutes as there is often significant overlap in the liquid flow rate ranges for various types of column internals. In some cases, a combination of trays and packings are used in distillation systems depending on the feed nature and composition, and the desired distillate.

Thus, it is always recommended to evaluate all practical solutions and approaches to come up with the most suited design. As a rule of thumb, tray columns are more efficient for columns with diameters above 0.6 meters. Otherwise, packed columns are more suitable.

One Response

Very good information, clear overview,

Thanks,,,,,,