Centrifugal pumps have the simplest design principle, making it the most widely used type of industrial pump. Still, most centrifugal pumps are not self-priming, so venting the gases out and filling with liquid (pump priming) has to be done manually.

Before starting up a centrifugal pump, follow this step-by-step checklist to ensure safety, minimize hazards, reduce maintenance costs and improve pump reliability:

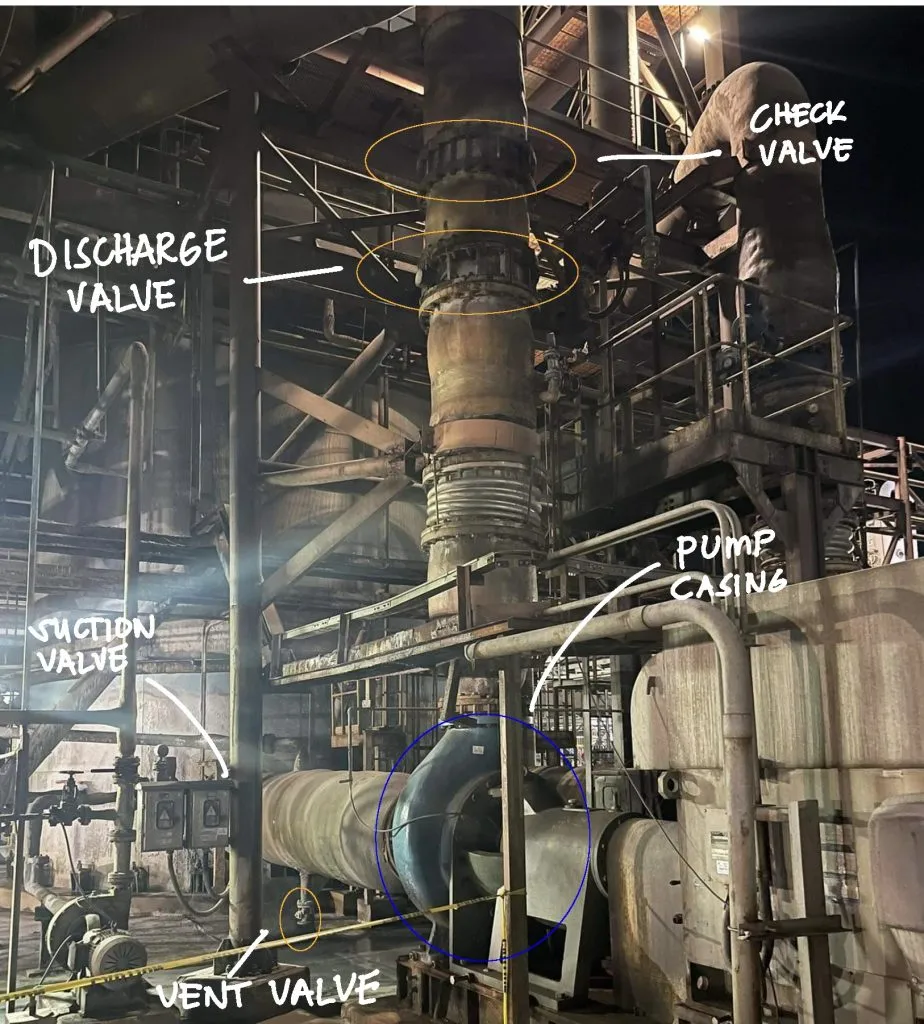

A picture of an industrial single-stage horizontal centrifugal pump used in a chemical processing plant is shown below as an example. Learn more about other types of industrial pumps here.

A centrifugal pumping system typically requires three main valves to control liquid flow — an inlet (suction) valve, an outlet (discharge) valve, and a check valve between the pump discharge nozzle and the discharge valve to avoid reverse flow and protect the pump from backpressure. Moreover, there is also a vent valve that opens and releases air.

If there is no check valve, the discharge valve must be closed before starting to prevent a sudden load on the power system when the motor starts. If the discharge valve is open during the start-up, the discharge head, which is the pressure at the pump’s discharge or the vertical distance that can pump liquid, will have a greater resistance to the pump — corresponding to higher power input. Closing the discharge valves will minimize resistance to the pump and will also prevent possible backflow.

There are many types of centrifugal pumps so there are no set procedures on how to start a centrifugal pump. It also depends on the centrifugal pump system, such as the pump’s relative location to the supply line. It’s best to refer to the company’s equipment operational manual. For sample purposes, the video below shows the basic start-up procedures.

1. Why is a check valve required at pump discharge?

Each pump’s discharge has a check valve to prevent backflow when the discharge valve is open. Selection should take into account the effect of the water hammer, which is the transient change in static line pressure as a result of a sudden change in flow. This may be caused by the starting/stopping of a pump or the opening/closing of a check valve.

2. Why are there no relief valves in centrifugal pumps?

The maximum pressure in a centrifugal pump system occurs when the discharge valve is closed and cuts off the flow. Even then, the pressure is just moderately above the working pressure. Relief valves are more necessary for positive displacement pumps.

3. Why are centrifugal pumps not self-priming?

Standard centrifugal pumps are not designed to be self-priming. Because centrifugal pumps do not have seals between the suction and discharge sides of the pump, it cannot draw liquid to the pump impeller unless the pump casing and impeller are filled with liquid.

4. How do you shut down a centrifugal pump?

Close the discharge valve first to take the load off the motor. Then, check if there are any check valve leaks to prevent backflow. Lastly, shut off the driver and leave the suction valve open.