Pump priming is a manual or automatic process done preliminarily on different types of industrial pumps to avoid mechanical pump problems by filling it with liquid to remove the gases in the pump and along its suction line before operation.

Pump priming is a very important start-up procedure for centrifugal pumps especially since it will cause significant problems if not correctly done.

If the pump is not primed, the air or gas inside the pump makes the pump gas bound causing cavitation.

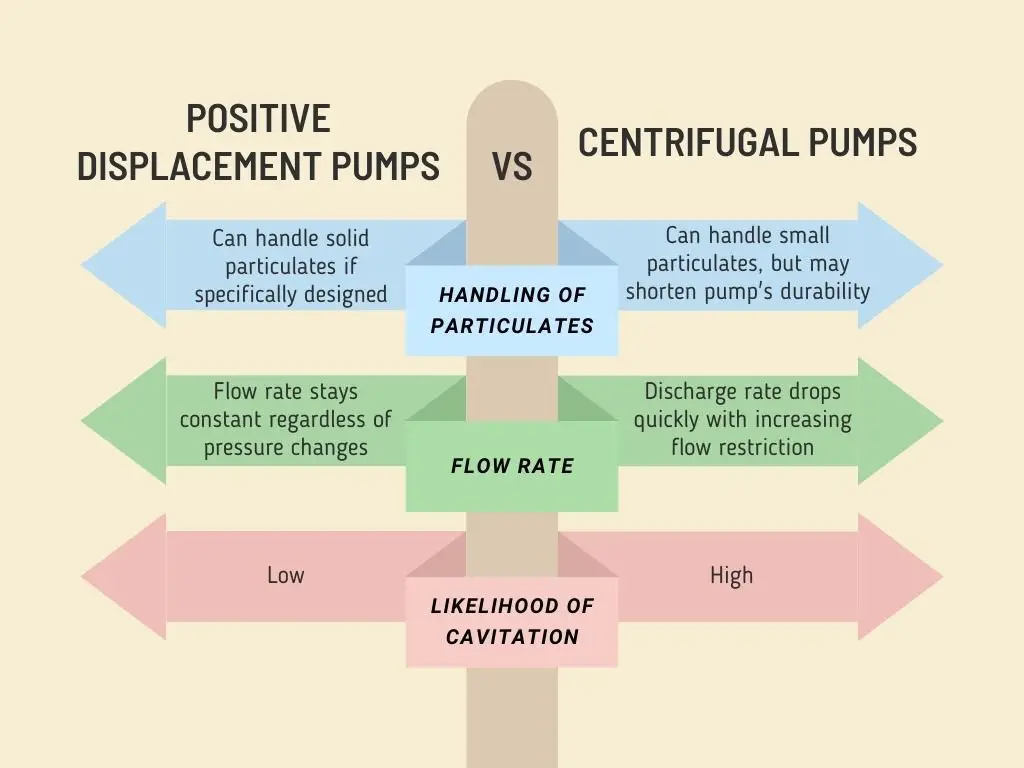

Cavitation in a centrifugal pump occurs when the impeller spins air or gas inside, preventing it from suctioning the desired liquid. It can cause the pump to overheat which can damage the pump internals. There could be a negative financial impact on the process operation due to pump maintenance and the downtime.

Pump priming steps differ depending on the location of the suction supply from the pump i.e.

All pumps need priming.

There are 2 types of pump priming mechanisms — self-priming pumps and manual priming pumps.

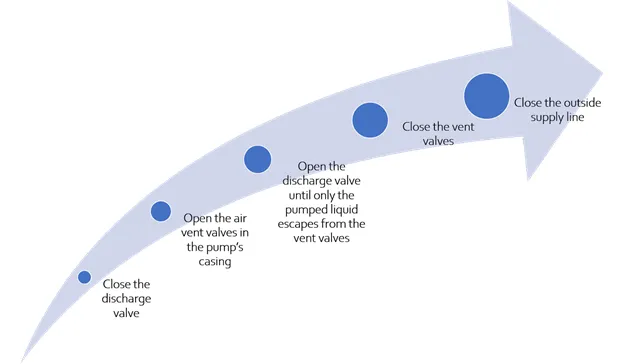

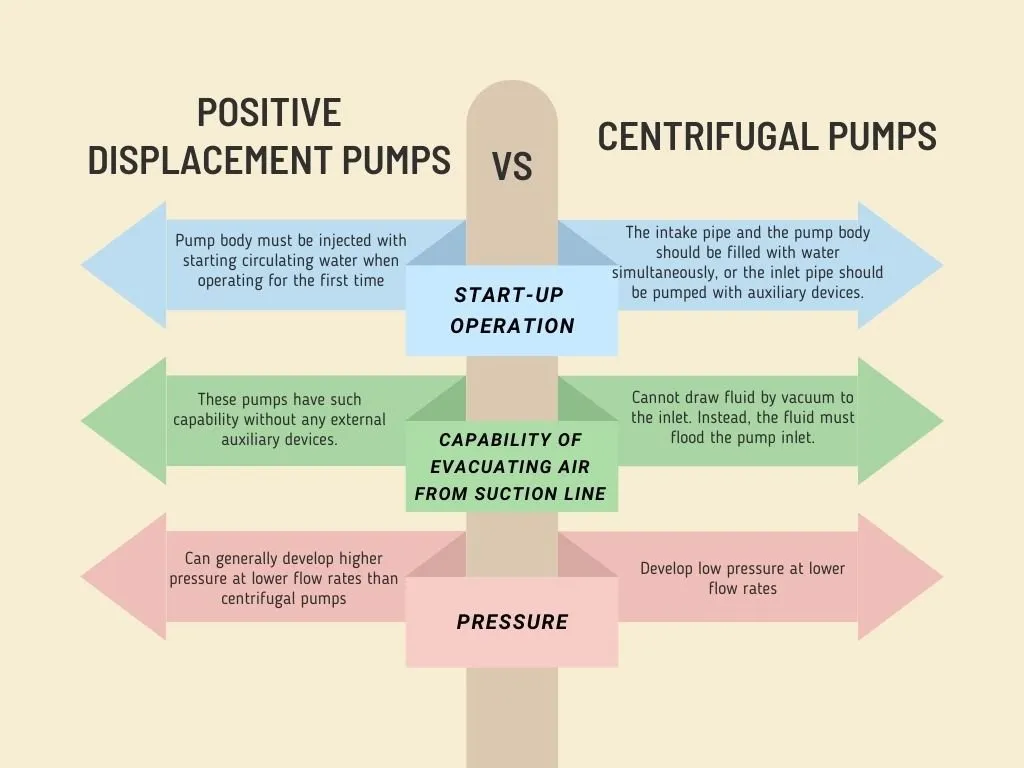

Self-priming pumps (such as the positive displacement pumps) create a partial vacuum to discharge water while evacuating entrapped air. Combining the air and liquid during the priming process forces the air to rise while the liquid goes down. The gravity then pulls the air-free liquid back to the impeller, which mixes with the excess air in the suction pipe. This process repeats until all air is displaced and vacuum forms in the suction pipe. Once this happens, atmospheric pressure forces the liquid to the suction pipe and towards the impeller to allow pumping to start.

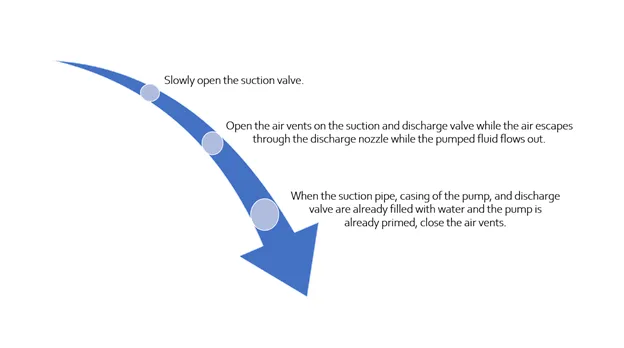

Meanwhile, the manual priming pumps (such as the centrifugal pumps) are not capable of evacuating the air between the suction and discharge line. So, it has to be done manually by filling the pump with liquid first and opening the vent valves to let out any air or gas in the suction line.

Thus, the main difference between the 2 mechanisms is the presence of seals between the suction and discharge sides.

Self-priming pumps have these seals while manual priming pumps do not.

By default, positive displacement pumps are self-priming, while centrifugal pumps are manual priming.

Centrifugal pumps must always be manually primed before operating. Although, there are cases where you can apply some modifications to the priming mechanism. For instance, centrifugal pumps can be modified to be self-priming with a surrounding ‘tank’ to retain some of the fluid.

Most self-priming pumps are positive displacement pumps. This includes rotary gear pumps, lobe pumps, vane pumps, and diaphragm pumps. They are capable of venting air from their suction line to some extent, depending on the effectiveness of the seals created from their close-tolerance parts, which prevent liquid from returning from the discharge to the suction pipe.

However, always check the operation manual or confer with an engineer first to ensure that the pump will properly function during start-up without priming.

1. Can a self-priming pump run dry?

No, because running dry, even for a short period, will cause damage to the mechanical seal resulting in pump failure.

2. Do I need to prime a self-priming pump?

Yes, even a self-priming pump needs to be primed prior to its initial operation. Regardless of the pump manufacturer, a priming chamber, installed internally or externally, will require filling prior to startup.