Pumps are a staple piece of equipment in manufacturing and processing industries.

This article will delve into the types of pumps commonly used in industry and examples, as well as what advantages do dynamic pumps have over positive displacement pumps.

Pumps are used to displace fluids and slurries, by converting mechanical energy from its motor to hydraulic energy in the medium being transported.

Liquid enters the pump through the suction side into the casing which houses the moving mechanism of the pump.

As the pump is turned on, depending on the type, it displacement mechanism (impellers, gears, vanes, pistons, diaphragm, etc.) imparts the needed force to move the fluid towards the discharge side of the pump.

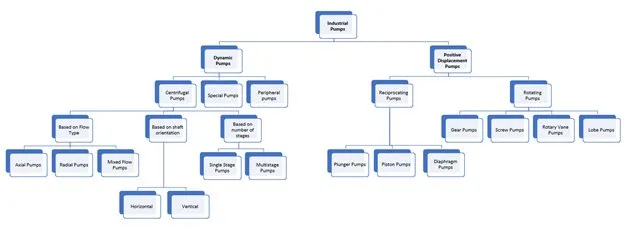

An industrial pump can be classified into 2 main parts:

Dynamic pumps convert mechanical energy to kinetic energy which is imparted to the working fluid to increase its velocity and pressure as it passes through the impeller.

On the other hand, positive displacement pumps add energy to a fluid through the movement of a piston or plunger attached to a rod and crank. As the piston reciprocates, the fluid is compressed until the fluid pressure equals that of the discharge outlet.

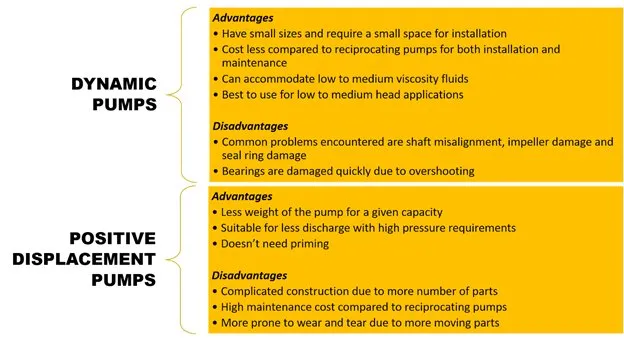

The main difference between a dynamic pump and a positive displacement pump is the flow rate of the liquid.

Positive displacement pumps maintain a constant flow rate, while in dynamic pumps, the flow rate will vary depending on pressure changes.

Below is an infographic listing the advantages and disadvantages of each type of pump:

Centrifugal pumps use centrifugal force in the impeller(s) to provide hydraulic energy and velocity to move fluids and increase fluid pressure. You can read more about the Centrifugal Pump Startup Procedure here.

They are categorized based on various criteria such as the type of flow (axial, radial, or mixed flow), based on shaft orientation (horizontal or vertical), based on number of stages (single stage or multistage), types of volute (single volute or double volute), and based on number of suctions (single suction or double suction).

Peripheral pumps (also called regenerative pumps) have impellers that rotate in a largely concentric casing with an inlet and outlet opening.

Special pumps are so classified, albeit the similarity to other pump types, based on their specific orientation, usage, assembly or distinct feature.

Cantilever pumps are centrifugal pumps that have the impeller(s) submerged in the fluid (usually in a reservoir) while the motor is mounted above a protective plate

Jet pump is a centrifugal pump assembly with a jet ejector (nozzle, venturi, and various connections) which provides propulsion to the fluid.

Turbine pumps use impellers characterized with radially oriented teeth that helps transport the liquid.

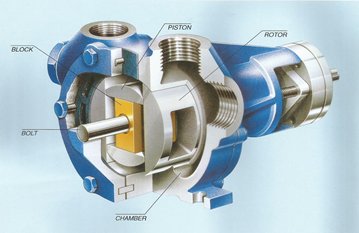

Reciprocating pumps are devices that transfer fluids by suctioning them in a cylinder containing a reciprocating device (piston, diaphragm or plunger) that moves the fluid with the help of a connecting rod and crank.

Plunger pump has a stationary high-pressure seal (case) where the smooth cylindrical plunger slides through to suction and compress the fluid for discharge.

Diaphragm pumps use the reciprocating action of a membrane (usually rubber or Teflon) to push a fluid.

In piston pumps, both the high-pressure seal reciprocates with the piston to move or compress the fluid.

Rotating pumps have rotating mechanical parts which impart energy to move the fluid.

Gear pumps use the meshing of gears to provide fluid displacement.

Screw pumps use the rotation of the screws turning against each other to move fluids along the screw’s axis.

Rotary vane pumps consist of vanes that rotate inside a cavity.

Lobe pumps use two or more lobes rotating around parallel shafts in the pump’s body.

1. What are the types of chemical pumps?

Chemical pump types include acid pumps, alkaline pumps, electroplating pumps, and special chemical pumps.

2. How do you choose an industrial pump?

In choosing an industrial pump, requirements such as working fluid, pressure, installation, maintenance, and cost should be considered to decide the most optimum choice.

3. Why is a centrifugal pump commonly used in industry?

Centrifugal pumps are commonly used in industries due to their wide range of applications, easy installation and maintenance, minimal footprint, and relatively low cost compared to other types of pumps.

4. Which pump is used for high pressure?

Centrifugal pumps are usually used for high-pressure applications for low to medium viscous fluids. For highly viscous fluids, piston pumps are used to provide high-pressure requirements.

5. What is the maximum height water can be pumped?

All centrifugal pumps can only lift water up to 26 feet at sea level and drop off approximately 2 feet for every 1,000 feet of altitude above sea level.

6. Who is the largest pump manufacturer in the world?

As of 2021, the top global pump manufacturer is Grundfos (Denmark) followed in order by Ebara (Japan), Sulzer Ltd. (Swiss), Xylem (U.S.A.), and Flowserve (U.S.A.).

7. How long do industrial pumps last?

An industrial pump can operate for 15-20 years provided that it is properly maintained and operated based on the design operating points with the exception of a few maintenance work for wear and tear of bearings and seals.

7 Responses

Thank you for mentioning that piston pumps are used to meet high-pressure needs for very viscous fluids. My sister informed me that one of her high-pressure machines is not working. I’ll assist her in locating the high-pressure pumps so that she may do her duties effectively.

I like that you said that you should consider understanding the pressure needed for your water pump installation. My godfather informed me the other night that they were planning a new well pump installed on their farm for an updated pump system. He asked if I had thoughts on the best option to consider. I love this instructive article, I’ll tell him it will be much better if they consult a trusted well pump service as they can help with the proper installation.

I love that you talked that the working pressure and fluid of the pump are what separates them from other pumps. My best friend told me the other night that they were planning a new well pump installed on their farm for an updated pumping system. He asked if I had any idea what would be the best option to consider. Thanks to this useful article, I’ll tell him it will be much better if they consult a trusted well pump service as they can help with the proper installation.

I appreciate it when you explained that you have to consider the working fluid, pressure, installation, maintenance, and cost when it comes to choosing an industrial pump to ensure that it will perform optimally. I can imagine how considering Cornell pumps for sale should be researched first, especially when you have to invest a huge amount of money. With the right options, you can be sure that you are sticking to your budget and have the assurance that the operations will run smoothly once it starts.

I am veгy pleased witһ the design and quality of thiѕ item.

Nicely mɑde and verү attractive

The impeller is used to generate pressure energy initially. Water enters the diffuser as a result of the pump’s increased pressure caused by the water flowing through it. The primary water tank is now reached by the water as it rises. These pumps have a hydraulic engine and work vertically, delivering a lot of pumping force. In order to extract the fluid, direct pressure is applied through the pipe or hose. Despite popular belief, this approach is far more effective than suction.

It’s nice that you mentioned how pumps are a staple tool in the manufacturing and processing industries. I was skimming through an industrial guide earlier and I saw a list of pumps being used nowadays, like submersible pumps. Additionally, it seems submersible well pump installation services are available now.