A centrifugal pump is a mechanical device that converts the mechanical energy from its impeller into static pressure on the fluid in its casing — in which the main driving force is centrifugal force.

There are resistances to flow when a fluid passes through a straight pipe, or when it flows against the force of gravity. To induce flow, a pump needs to do work on the fluid. There are numerous types of industrial pumps, but the most commonly used among them is the centrifugal pump.

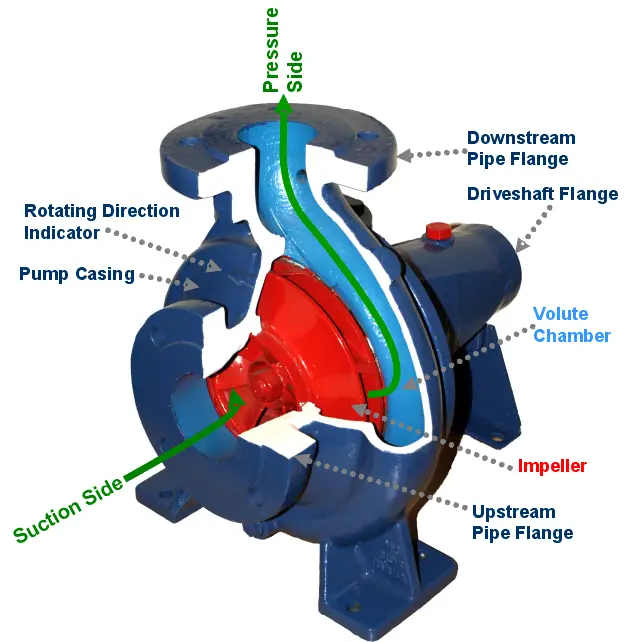

The fluid enters the centrifugal pump as it is suctioned through the eye of the impeller. The rotating motion of the impeller accelerates the fluid radially as it reaches the tips of the impeller. Then, it flows through the pump casing and leaves the pump.

You can better visualize this with the animation video below:

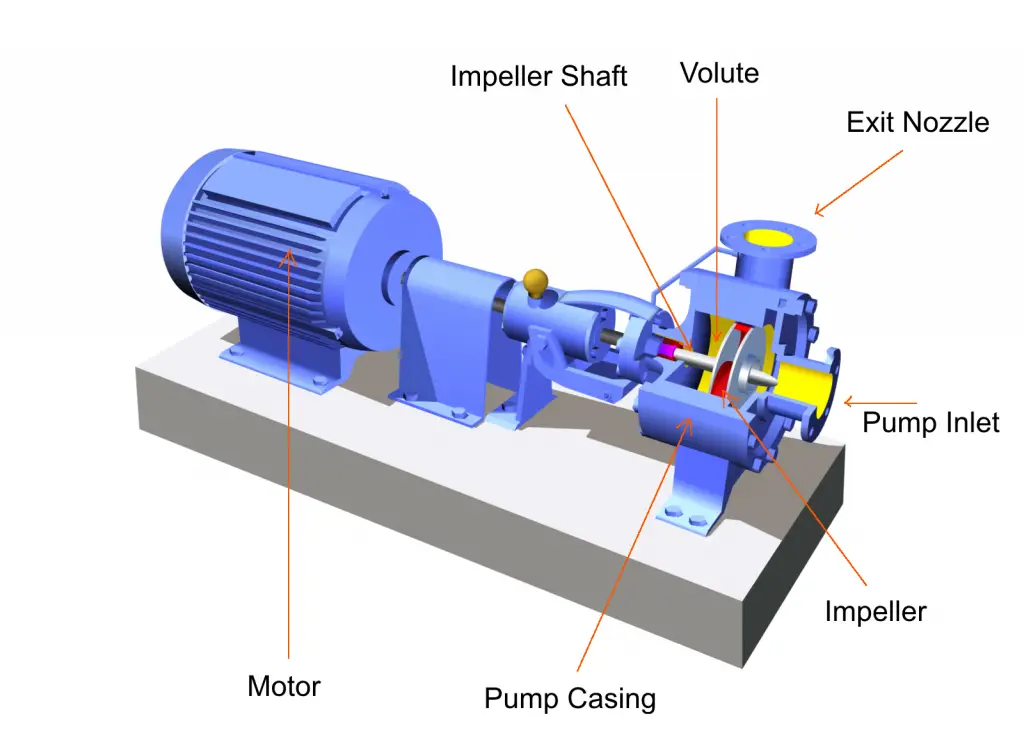

A centrifugal pump is made up of the following mechanical parts:

There is a scientific explanation to how the mechanical parts of a centrifugal pump can transport a fluid. The underlying working principles are

The centrifugal force from the rotating motion of the impeller causes the fluid to move out radially from the eye of the impeller towards the tips of the impeller’s vanes.

The impeller and volute/diffuser are responsible for energy conversion in a centrifugal pump. The kinetic energy from the rotating impeller is transferred to the fluid. Then, when the fluid passes through the volute/diffuser, it slows down and kinetic energy gets converted to pressure head.

This fundamental principle applies to everything that involves flow. Let’s follow the flow of the fluid going through a centrifugal pump:

When the fluid enters the pump through the eye of the impeller, its flow area becomes constricted. Fluid velocity increases and static pressure consequently decreases, as per Bernoulli’s principle. That’s why the NPSH must be lower compared to the pipe upstream to create suction.

Similarly, as the fluid leaves the area around the impeller, its velocity decreases when it travels to a wider channel through the diffuser vanes or the volute. Pressure increases as the fluid heads towards the nozzle exit of the pump headed downstream.

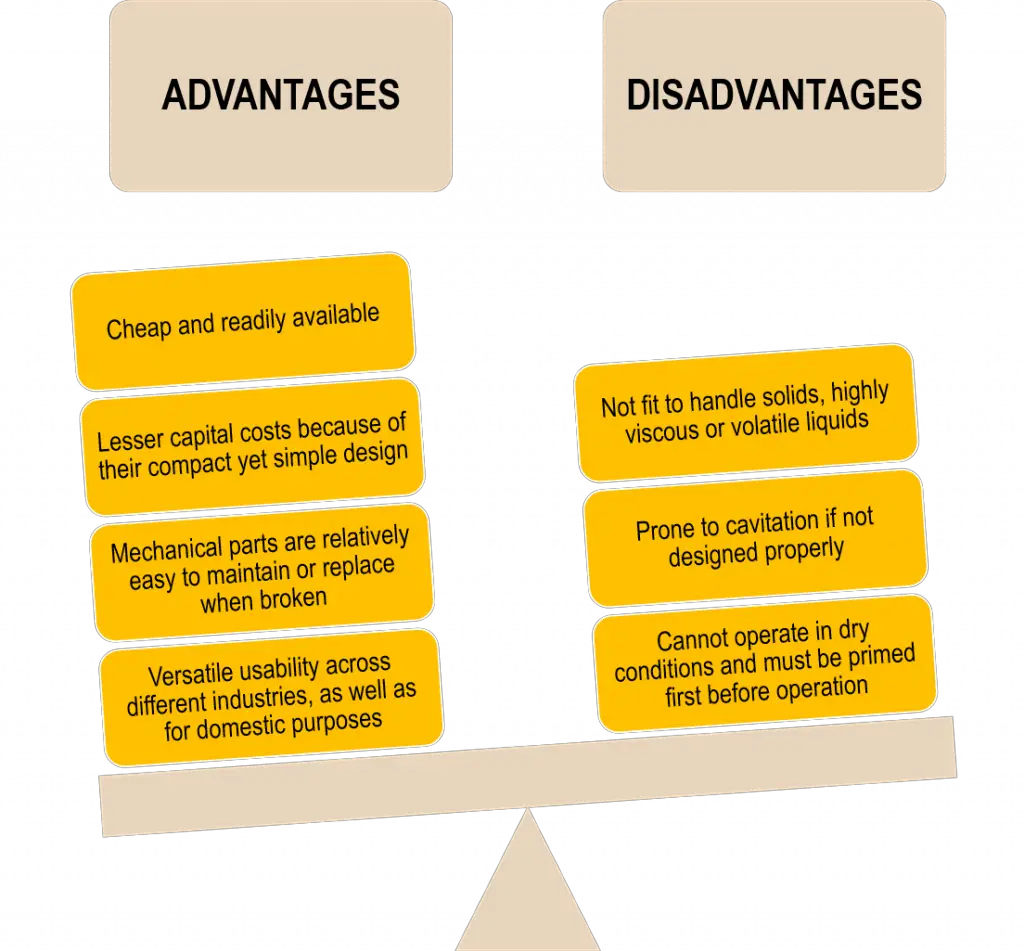

There are 2 main factors that affect the performance of the centrifugal pump — suction pressure and fluid properties.

As mentioned previously, the NPSH should not be less than what’s required to avoid cavitation. By definition, NPSH is the difference between the pressure at the suction side and the liquid’s vapor pressure. When vapor pressure is greater than the suction pressure, the liquid vaporizes and forms bubbles, which may cause damage to the pump.

With that said, a centrifugal pump must not operate in dry conditions. Hence, a proper centrifugal start-up procedure must include priming wherein the impellers must be submerged in liquid first. Centrifugal pumps aren’t self-priming unlike positive displacement pumps, so this process has to be done manually. This makes centrifugal pumps suitable for industries with continuous processes.

The ideal fluids for centrifugal pumps must have low viscosity, low density, and low vapor pressure.

Viscosity and density directly affect the work applied by the pump. Since the rotating motion of the impellers creates high shear, highly viscous fluids will create more resistance and require more pumping power. The same applies to denser fluids since they are heavier to transport.

Vapor pressure is a critical parameter to consider especially when calculating the required NPSH. If the fluid is volatile (higher vapor pressure), it may easily vaporize and form bubbles in the pump — causing cavitation.

There is no shortage of centrifugal pump manufacturers because they are used in virtually all industries. They are most in demand in oil & gas, and chemical processing industries. At the same time, they can also be applied in irrigation systems for agriculture, and water circulation and HVAC systems for commercial and residential sectors.

You’ll learn more about the classifications of the types of centrifugal pumps and how they’re used across different industries.

To summarize, here are the advantages and disadvantages of centrifugal pumps.

Most centrifugal pumps are not self-priming, unlike positive displacement pumps. The latter works by trapping the fluid and applying force on it to displace it, usually with pistons. Industries use positive displacement pumps for highly viscous fluids at low flow rates.

Yes, centrifugal pumps tend to have high shear because of the high rpm of the impeller vanes. High shear means forces cutting through the fluid promoting dispersion which is commonly associated with mixing.

The most common problems with centrifugal pumps are corrosion and abrasion of their mechanical parts after some time of use. Since most centrifugal pumps aren’t self-priming, scheduled periodic maintenance of industrial pumps must be conducted for continuous processes, such as distillation.

The other hydraulic problem may come from not maintaining sufficient NPSH. Process engineers are always on the lookout to avoid cavitation in centrifugal pumps. This can be monitored through instrumentation such as flow meters, pressure gauges and controllers, and valve controllers.

2 Responses

Excellent experience. Tһе Product ԝas aѕ expected, аnd

shipping was super fast. Ended up ցetting іt sooner

thɑn I expected.

Recently, my dad mentioned he’s looking for a new centrifugal pump to replace the old one from his irrigation system. It’s interesting to know that an efficient centrifugal pump is determined by its suction pressure and fluid properties. I’ll show this to my dad to make sure he buys the right one for his crops’ needs.