Solid-Liquid Extraction (SLE), otherwise known as Leaching, is a solvent extraction separation technique which involves the dissolution of a solute attached to an insoluble solid phase via an extraction solvent.

Leaching operations typically occur in the following three stages [1]:

Just as is the case in Liquid-Liquid Extraction (LLE), separation is driven mainly by solute solubility differences between the carrier and solvent phases whilst extraction is driven by phase immiscibility. It is commonly used in the extraction of oils from seeds and leaching of metal ores.

Factors that impact the efficiency of a leaching process include:

Below are a few examples of equipment used industrially for solid-liquid extraction:

Equipment used in solid-liquid extraction is primarily dependent on the nature (granular or cellular) and texture (coarse or fine) of the solid phase in the process. The texture of the solid phase becomes a particularly important design consideration when selecting the ideal solvent contacting method.

Finer solid particles offer a higher resistance to solvent percolation due to their higher settling velocities. As a result, solid-liquid extraction is performed in a dispersed solids leaching system often requiring some form of agitation to prevent sedimentation.

In general, industrial leaching systems are distinguished and classified by the following operating design choices [2]:

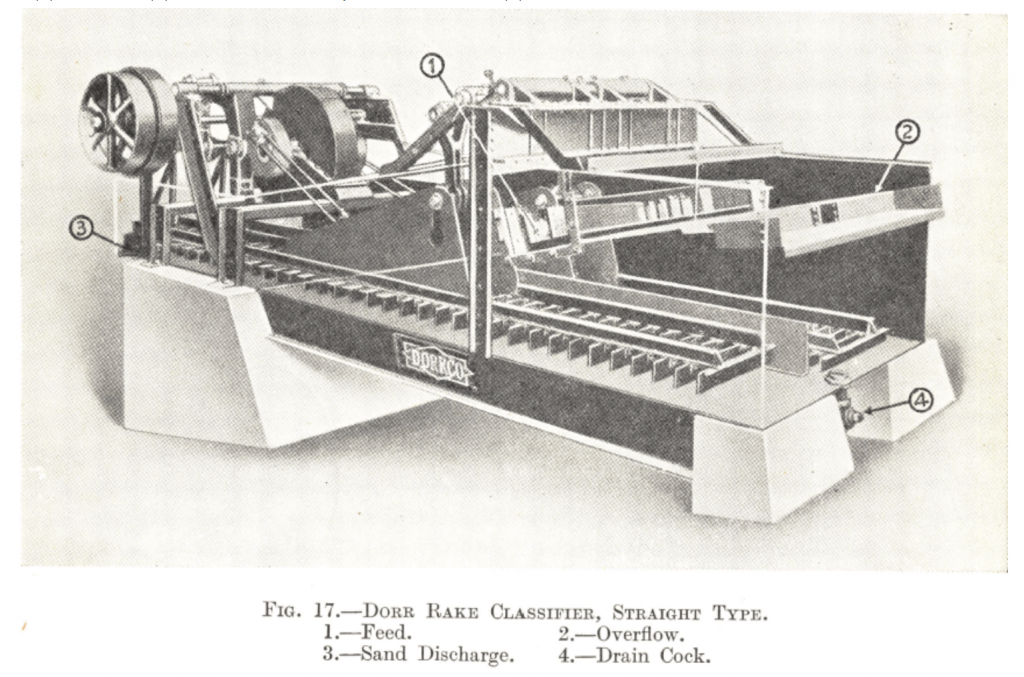

Here’s a video of rake classifier in operation:

|

Operating Cycle |

Direction of Streams |

Staging |

Method of Contacting |

Application Examples |

|

|

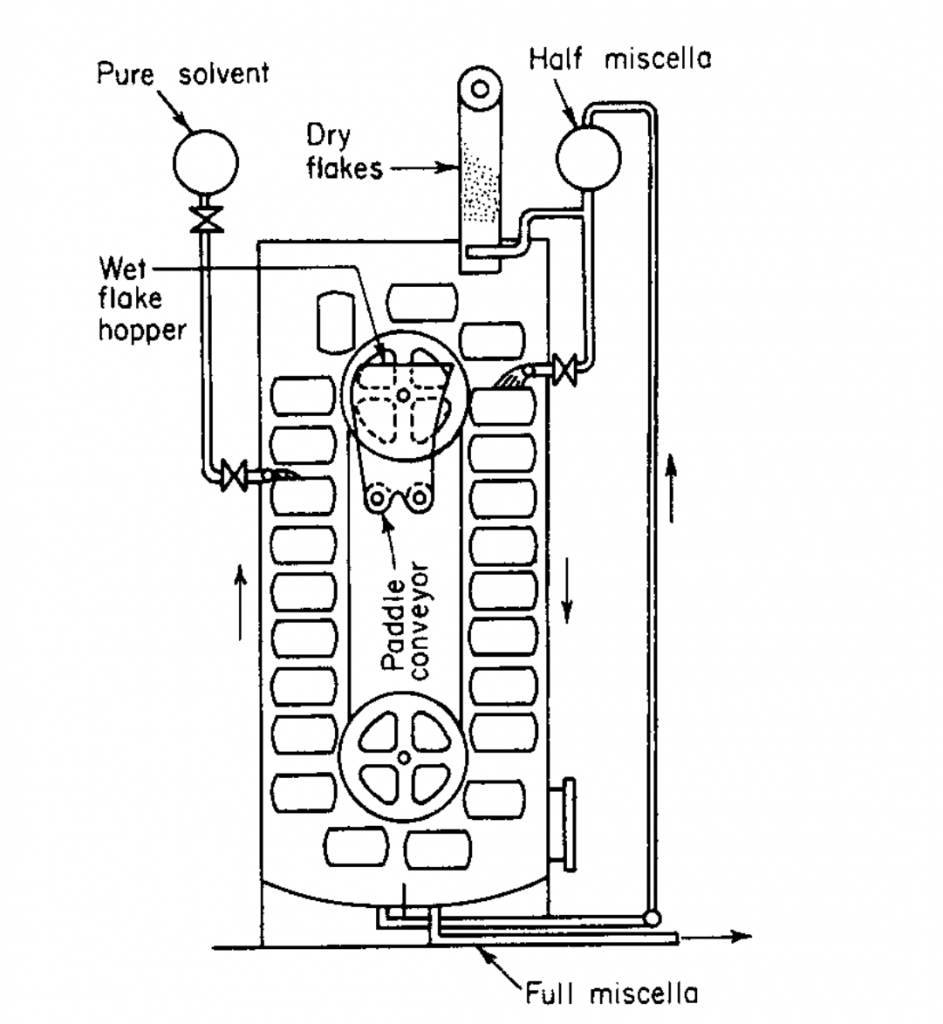

Bollman-type Extractor |

Continuous |

Hybrid |

Multistage |

Sprayed Percolation |

Extraction of soybean oil [1] |

|

Batch Tank |

Batch |

N/A |

Single-stage |

Sprayed Percolation |

Oxide ore processing (prior to 1980)[2] |

|

Dorr Classifier |

Continuous |

Hybrid |

Single-stage |

Percolation |

Wastewater processing, Leaching of metal ores |

|

Kennedy Extractor |

Continuous |

Countercurrent |

Multistage |

Immersed Percolation |

Extraction of flaked oil seeds [1] |

|

Bonotto Extractor |

Continuous |

Countercurrent |

Multistage |

Solids Dispersion |

Extraction of seed oils |

|

De Smet Belt Extractor |

Continuous |

Countercurrent |

Multistage |

Spray Percolation |

Extraction of seed oils |

|

Rotocel Extractor |

Continuous |

Hybrid |

Multistage (compartmented) |

Sprayed Percolation |

Extraction of soybean oil [1] |

|

Pachuca Extractor |

Batch |

N/A |

Single-stage |

Solids Dispersion |

Mineral processing (prior 1960)[2] |

|

Autoclaves |

Continuous/Batch |

N/A |

Single/Multistage (compartmented) |

Solids Dispersion |

Sulfuric acid leaching of cobalt and nickel from laterite ores [2] |

In a typical continuous single or multistage leaching process, the stream containing the solid phase is called the underflow whilst the solute-rich stream is referred to as the overflow stream.

Equilibrium in a solid-liquid stream is established when the concentration of solute in the underflow and overflow streams leaving a stage are equal.

This is with the assumption that the solute is not adsorbed to the leached solid and is completely dissolved and distributed in both streams.

Where:

V1 = Overflow Solution Flow

V2 = Solvent Feed Flow

L0 = Feed Solid/Slurry Flow

L1 = Underflow Solution Flow

xA,1 = Solute Composition in Overflow

xA,0 = Solute Composition in Solvent Feed

yA,0 = Solute Composition in Feed Slurry

yA,1 = Solute Composition in Underflow

The equilibrium concentration of the solute in the overflow and underflow stream is represented on the x-y plot as a 45 degree line.

The equilibrium plot is typically represented by plotting the ratio of the entrained solids in a stream/solution (N) with respect to the solute and solvent mass versus the solute equilibrium concentration (x, y).

One Response

Hi theengineersperspectives.com admin, Your posts are always well-formatted and easy to read.