Six Sigma-certified chemical engineers are proficient in process capability tools that are focused on improving process quality. In this topic, you will learn more insights into how beneficial a Six Sigma certificate is to chemical engineers.

Continuous Improvement Lead, Lean Six Sigma Master Black Belt, Project Completion Coach at Cargill

Yellow Belt and Green belts really add value to the engineering toolbox. Each and every Green Belt that I worked with obtained new challenges, promotions, [or] new roles inside or outside the current company within one year after certification

Process Development Engineer at Tesla, Six Sigma Black belt

If you are looking into process engineering/manufacturing-related jobs then six sigma would give a head start

Six Sigma is a statistical and data-driven process that uses a set of quality-control methods and tools for business process improvement and quality management. It emphasizes finding process defects, determining the causes, and improving current processes to increase the reliability and repeatability of process results. The improved process efficiency, in turn, also improves the quality of products for the customers — significantly boosting business profit, customer satisfaction, and employee confidence.

This management ideology is part of the total quality management philosophy on continuous improvement. Since organizations cannot reach perfection, they should always measure their performance and take continuous actions to advance it.

Six Sigma tools equip chemical engineers to lead initiatives for improving process efficiency and the quality of products and services to the customers. This is achieved by focusing on reducing total defects and decreasing work in progress which translates to increased capacity, output, and quality.

It is beneficial for chemical engineers to pursue a Six Sigma certification since it can help them improve, optimize, and solve problems in existing industrial processes. These are the advantages of chemical engineers with a Six Sigma certificate:

With Six Sigma methodologies in place, a chemical engineer who oversees large-scale and complex processes can use these tools to make them more efficient. Sample areas that a chemical engineer could make good use of these tools are the following:

There are no prerequisites for the Six Sigma program. Six Sigma certifications can be earned if you meet the following requirements:

There are several ways to earn a Six Sigma Certification by accredited training providers. Unlike in ISO, there is no central certifying body in Six Sigma. Usually, master black belts can certify individuals as long as the applicant meets the minimum requirements.

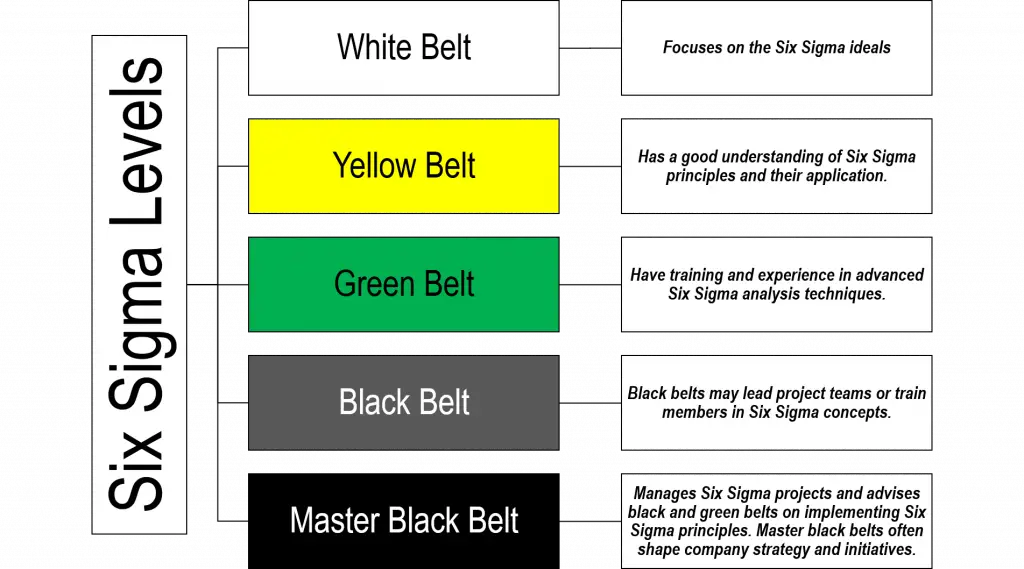

Six Sigma certification has levels where each belt represents an improved understanding and experience in this principle. Each belt is earned through course-based training and on-the-job experience. Accreditation bodies such as the American Society for Quality provide these certifications, which are:

Being a chemical engineer with a Six Sigma certification does not only reduce defects in processes but also helps organizations determine threats and recognize new opportunities for their growth in order to thrive within competitive environments. Not only does Six Sigma benefit the organization, but also the career development of a chemical engineer.

Yes, because the skills you have already mastered and the hands-on training in project management, cost reduction, revenue improvement, leadership, and quality control can help you stand out to employers.

Six Sigma Master Black belt is the highest level of Six Sigma achievement. At this level, you already have a thorough understanding of shaping strategy, developing key metrics, acting as a consultant, and coaching black and green belts.

Six Sigma training cost around $300 to $1,050.

One Response

thanks for info