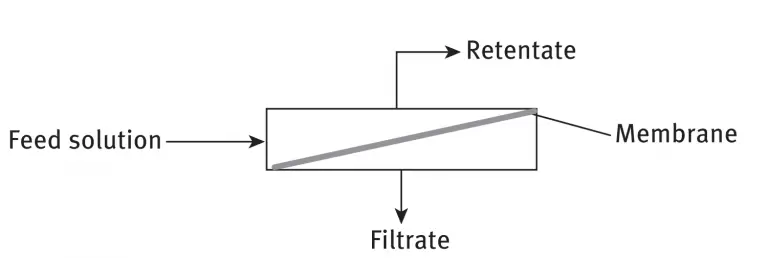

A membrane separation process is a process in which a feed stream is sent through a selective barrier known as a membrane, in which some components are retained (retentate) and some components pass through (filtrate). The unwanted component of the feed mixture is retained and does not pass through the membrane while the desired components can pass through.

A pressure driven membrane process is simply a membrane separation process where the feed solution is forced through a semipermeable membrane via a hydrostatic pressure gradient. Pressure is one of the driving forces in membrane separation amongst concentration gradient, chemical potential, electrical potential and temperature difference.

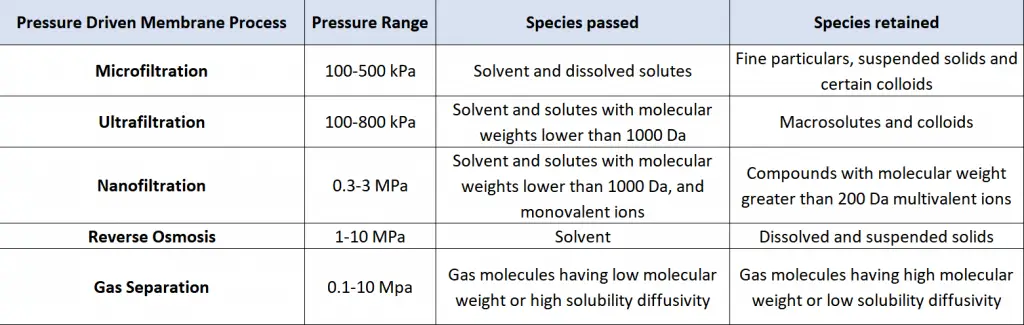

The different types of pressure driven membrane separation are as follows:

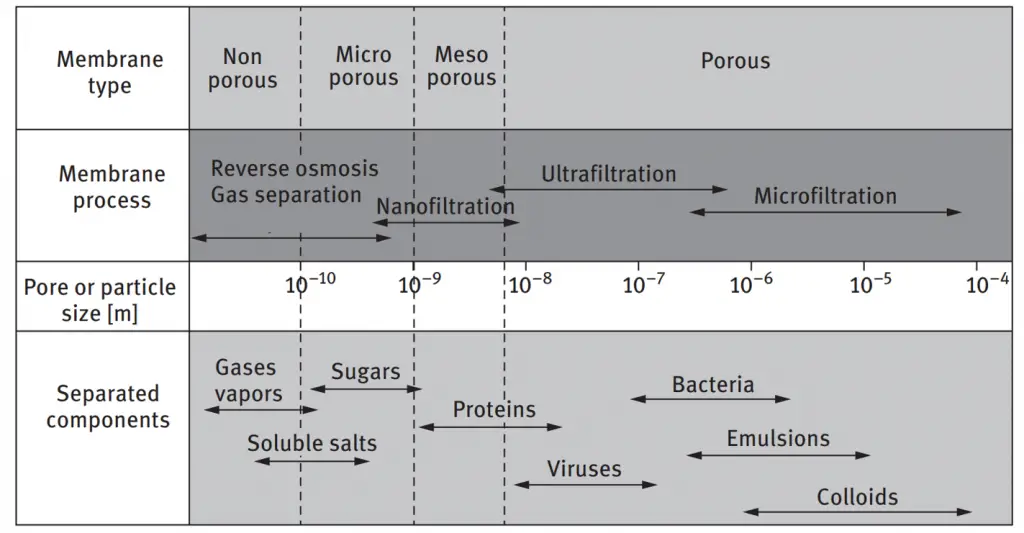

Pressure-driven membrane processes can be categorized based on their membrane types. These membrane types are as follows:

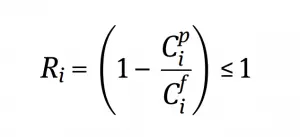

The rejection of the membrane (Ri) demonstrates the separation capability of the membrane by expressing a number between 0 and 1 that reflects how many particles from the feed stream have been removed through the membrane.

There are 3 cases here:

If the feed concentration (Cf) equals the permeate concentration (Cp) (i.e. there was no decrease in concentration of particles after the solution moves through the membrane, this means that the Ci/Cf ratio equals 1, and hence, Ri = 0. This means that there was no rejection by the membrane and it was useless for the given application.

If the permeate concentration (Cp), or whatever leaves the membrane, equals 0, then the Ci/Cf ratio = 0, and Ri = 1. This means that the membrane did a perfect job of removing everything from the feed stream.

As Ri increases, this effectively reflects how much better the membrane is at separating the filtrate from the feed stream.

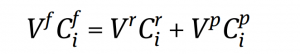

The mass balance equation above holds true under the following assumptions

Here V represents the volume and C the concentration where ‘f’, ‘r’ and ‘p’ represent filtrate, retentate and permeate respectively. This equation can be rearranged to solve for the concentration of a component in the filtrate or retentate streams.

Microfiltration has a pressure range between 100 and 500 Kpa. The species passing through the membrane are solvents and dissolved solutes, whereas the species retained are fine particulars, suspended solids and certain colloids. On the other hand, ultrafiltration has a pressure range between 100 and 800 Kpa. The species passing through this membrane are Solvent and solutes with molecular weights lower than 1000 Da, whereas the species retained are Macrosolutes and colloids.

A low pressure membrane is typically considered to operate anywhere between 68 Kpa to 207 Kpa.

A gravity driven membrane is essentially a pressure driven membrane since it utilizes the hydrostatic pressure from the feed solution.

2 Responses

Dear theengineersperspectives.com admin, Thanks for the well-researched and well-written post!

Thank you very much for sharing, I learned a lot from your article. Very cool. Thanks. nimabi