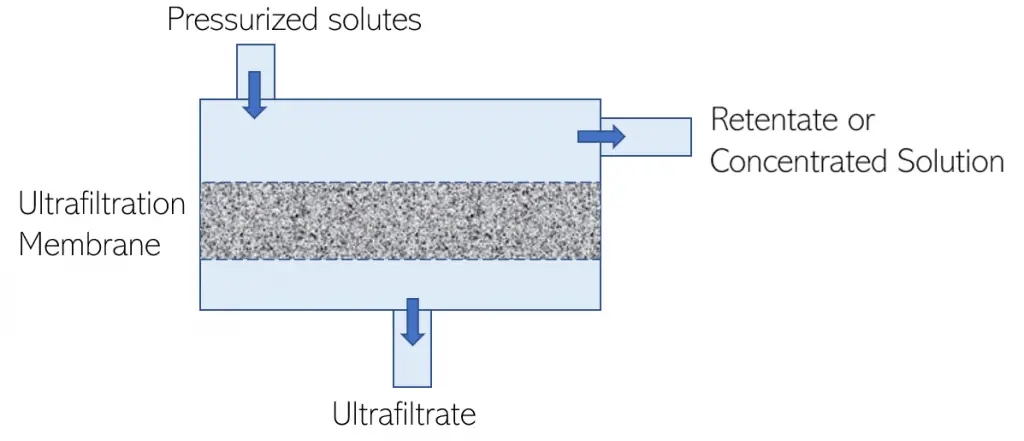

Ultrafiltration is a porous pressure driven membrane process where size exclusion is the primary removal mechanism for colloids, particles and other macromolecules. In ultrafiltration, the species passed through the membrane pores (typically 1-100 nm) are called the ultrafiltrate, and are solvent and solutes with molecular weights lower than 1000 Da.

The species retained are molecules with larger molecular weights that are greater than 1000 Da and less than 500,000 Da. The species that are too big to pass through the membrane are called the retentate, and known as the concentrated solution since all the components that could not permeate the membrane are now concentrated in this stream.

The driving force of an ultrafiltration process is a pressure gradient which operates typically between 1-10 bar.

Membranes used in ultrafiltration e can be classified as either:

Membranes can be a range of materials such as ceramic, polyimide, polysulfone, polyethersulfone, polyvinylidene fluoride, cellulosic, polyacrylonitrile, or aliphatic polyamides. Due to the fact that relatively higher molecular weight species are removed by ultrafiltration, the difference in osmotic pressure across the membrane is negligible, thus allowing high flux rates to be achieved with low applied pressures.

Relative to the other pressure driven membrane separation processes, ultrafiltration is more selective than microfiltration, but less selective than nanofiltration, reverse osmosis or gas diffusion. Ultrafiltration has a wide range of applications such as wastewater treatment, pathogen removal, juice concentration and clarification, blood treatments, effluent filtration and more. We will discuss the application in more detail in this article.

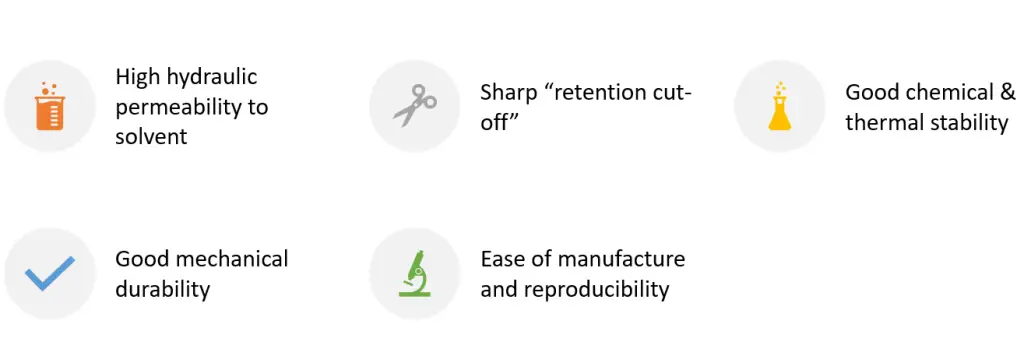

In order for ultrafiltration to be carried out efficiently, it must have following features:

Hydraulic permeability essentially provides performance information on the mass transport of components in the feed stream under the hydrostatic pressure force.

The retention cut off is a characterization method for the membrane pore size and distribution. Ensuring that there is a “sharp” retention cut off ensures that components in the feed stream greater than 1000 Da are retained by the filter to a degree of certainty related to the application.

The chemical and thermal stability are related to the degree of protection that the membranes have against chemical action or modifications in temperatures. Strong chemical and thermal stability allow the ultrafiltration membrane to be used in a larger range of applications.

Mechanical durability, ease of manufacture and reproducibility are extremely important in making sure ultrafiltration modules are able to be easily replicated for commercial applications, and are long-lasting without the need for excessive maintenance.

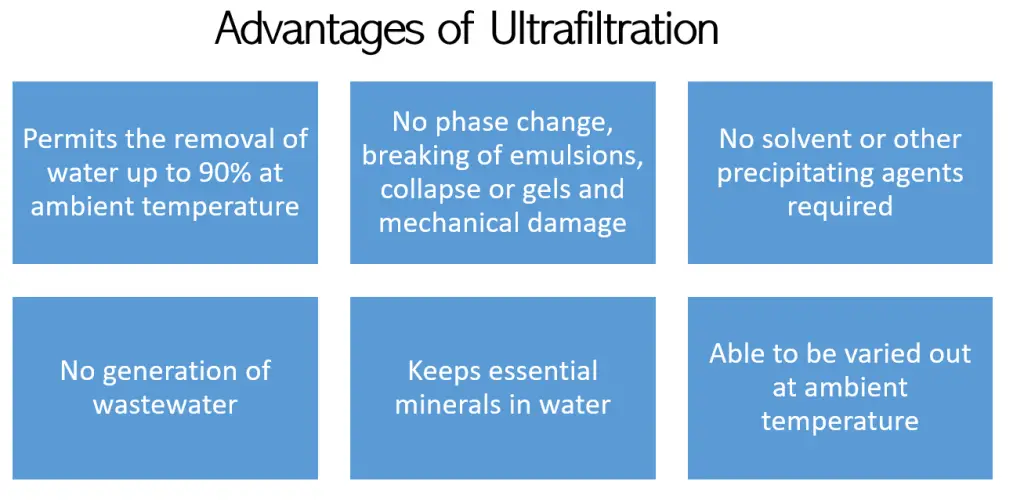

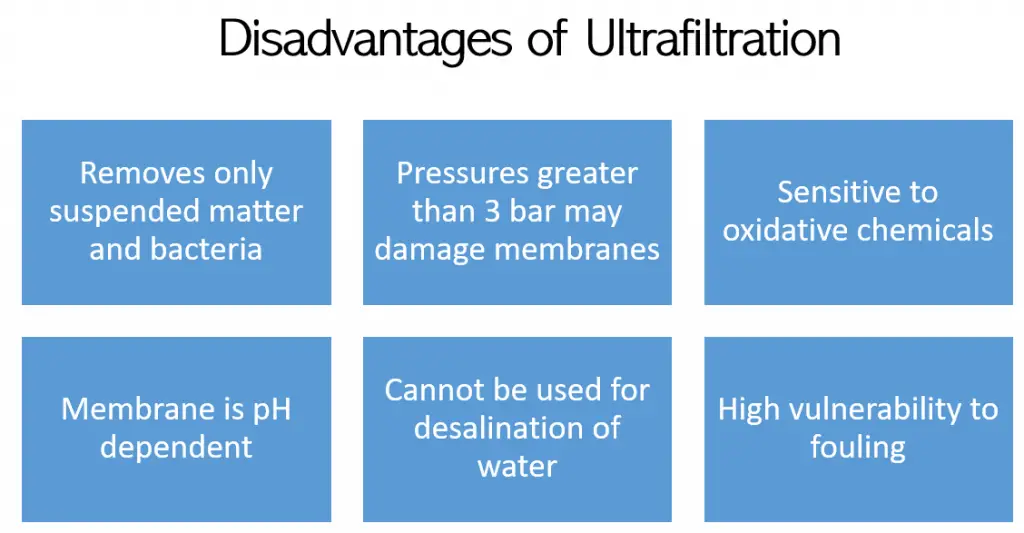

Some of the advantages of ultrafiltration:

Some of the advantages of ultrafiltration:

Ultrafiltration modules are compact ultrafiltration units that are manufactured for commercial or industrial usage.

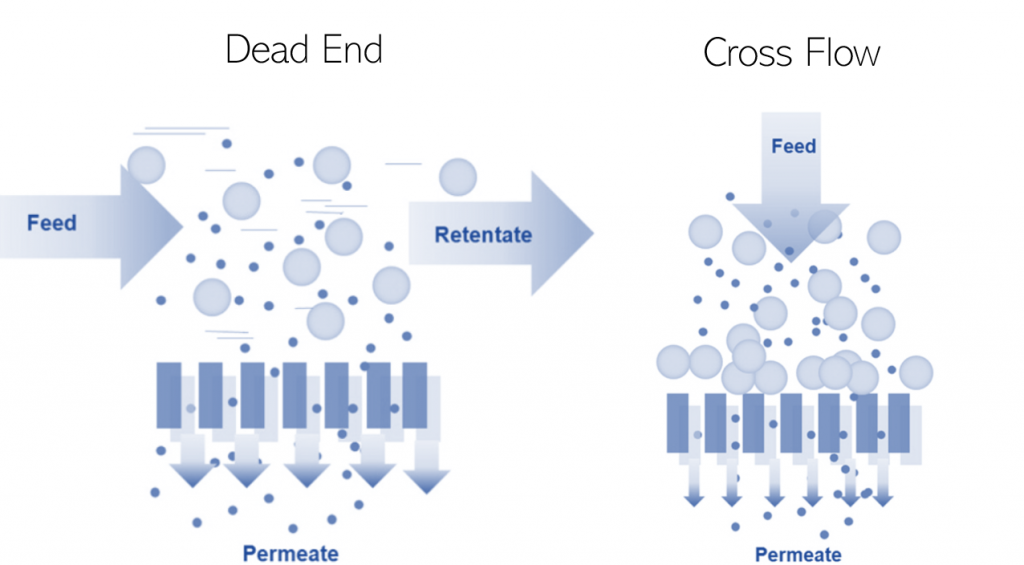

There are 2 main operating features that can be used to break down the ultrafiltration modules:

As the name suggests, these ultrafiltration modules have a constant pressure and variable flux. The variable flux is caused by a rapid circulation of the feed solution across the membrane surface in an effort to control fouling – also known as cross flow operation. .

These systems were very popular until the 1990s, however as the constant flux/variable pressure modules were introduced, they became less popular.

There are 4 basic constant pressure/variable flux, or cross flow modules available. Choosing which module type to use is highly dependent on the specific ultrafiltration application.

For example, spiral wound ultrafiltration membranes are preferred with applications where there are little to no fouling tolerances such as virus removal from therapeutic products. On the other hand, in applications such as separating oil/water emulsions, the ease of cleaning and fouling resistance of the tubular modules outweighs their high cost and energy consumption.

The development of these modules came around 1995 with the classic example being known as the submerged membrane module whereby the constant flux is maintained by a variable speed pump.

In this module, the flux is maintained through controlling the pressure, and the fouling of the membrane is controlled by air sparging as well as regular backflushing.

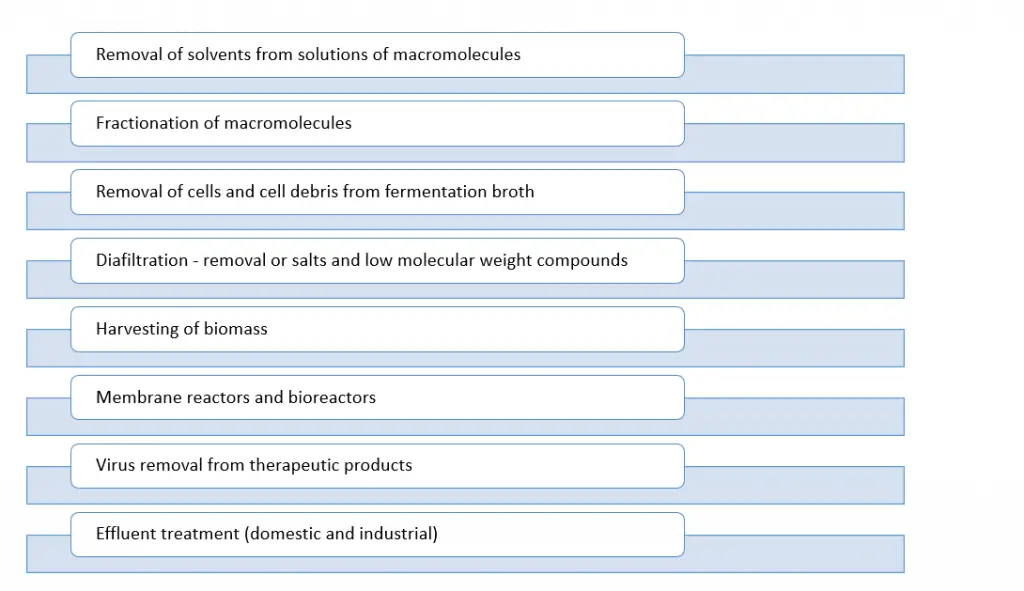

Some of the applications of ultrafiltration include:

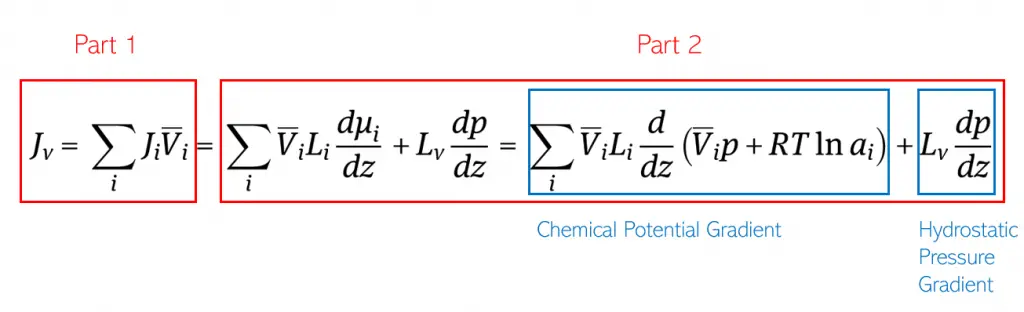

The volumetric flux in the ultrafiltration membrane is expressed as the sum of the flux from all the individual components.

We can see that in the first part of the equation above, Jv, or the volumetric flux through an ultrafiltration membrane, is equal to the sum of the flux of each individual component multiplied by their respective partial molar volume.

The second part of the equation shows this same equation expanded as a function of the chemical potential gradient and hydrostatic pressure gradient.

Before you get freaked out by this equation, let’s look at a couple assumptions that can be used to simplify this equation down to be used in a practical application.

Assumptions

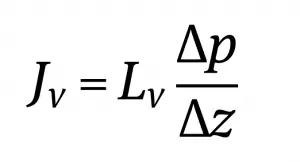

When we apply these 4 assumptions, we are left with the most practical equation for determining the volumetric flux through an ultrafiltration membrane.

Jv – Volumetric flux through a ultrafiltration membrane

Ji – flux

Vi – Partial molar volume

Lv – Hydrodynamic permeability of the membrane

Δp – Pressure difference between the feed and filtrate solution

Δz – Membrane thickness

i – refers to the component in the solution

Ultrafiltration is simply one of the pressure driven filtration methods in which particles that are larger than the membrane pore size are excluded from the clarified stream, also called the ultrafiltrate.

Your kidneys are an incredible organ that serve the purpose of filtering excess fluid and waste from your blood. When people’s kidneys fail, dialysis is a medical treatment that essentially performs the same function as your kidneys by cleaning your blood.

There are two types of dialysis – hemodialysis and peritoneal dialysis. In hemodialysis, the filtration of your blood is done outside the body using an external machine known as a dialyzer. In peritoneal dialysis, the procedure helps the body perform its filtering functions internally.

Ultrafiltration (UF) is utilized in hemodialysis through a dialysis membrane. This membrane filters the fluid and waste using a pressure differential and allows for the excess fluid and waste to be removed.

Ultrafiltration is also utilized in peritoneal dialysis, however in this case, the ultrafiltration membrane that is used is the lining of your stomach.

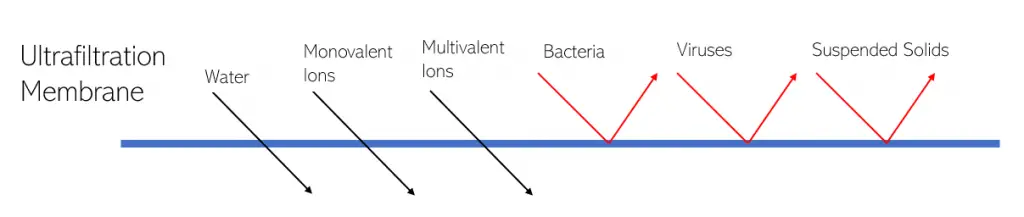

Ultrafiltration membranes can remove some viruses from water. Since size exclusion is the primary mechanism for filtration, if the virus size is smaller than the pore size of the ultrafiltration membrane (1nm – 100nm), then the membrane will be ineffective in filtrering out the virus. Viruses have varying sizes and can be as small as 20nm, which would have a higher effectiveness in penetrating the membrane and entering the ultrafiltrate stream.

Ultrafiltration can indeed remove bacteria. The smallest known bacteria is the mycoplasma genitalium and can be as small as 200 nm. Since the ultrafiltration membrane has a maximum pore size of approximately 100 nm, we can say that the membrane is highly effective in filtering out bacteria.

One Response

Dear theengineersperspectives.com webmaster, Your posts are always well researched.